Bookkeeper CEO参与制定了ISO/TS 18344脱酸技术规范

时间:2018-12-07 08:58:47来源:Bookkeeper

© ISO 2016

Effectiveness of paper deacidification processes

批量脱酸的效果

Efficacité des procédés de désacidification du papier

TECHNICAL SPECIFICATION ISO/TS 18344

ISO/TS 18344 技术规范

Reference number ISO/TS 18344:2016(E)

参考号:ISO/TS 18344:2016(E)

First edition 2016-02-01

第一版 2016-02-01

ISO/TS 18344:2016(E)ii © ISO 2016 – All rights reserved

COPYRIGHT PROTECTED DOCUMENT 版权所有 翻版必究

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of the requester.

非特殊声明不得以电子或照片,万维网或局域网等任何形式转载和使用。如有需要可以向ISO及其所属成员提交许可申请。

Foreword / 前言

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO member bodies). The work of preparing International Standards is normally carried out through ISO technical committees. Each member body interested in a subject for which a technical committee has been established has the right to be represented on that committee. International organizations, governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

国际标准化组织(ISO)是由各国标准化团体(ISO成员团体)组成的世界性的联合会。制定国际标准的工作通常由ISO的技术委员会完成。各成员团体若对某技术委员会确定的项目感兴趣,均有权参加该委员会的工作。与ISO保持联系的各国际组织(官方的或非官方的)也可参加有关工作。ISO与国际电工委员会(IEC)在电工技术标准化方面保持密切合作的关系。

The procedures used to develop this document and those intended for its further maintenance are described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the different types of ISO documents should be noted. This document was drafted in accordance with the editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

在ISO/IEC导则第1部分中规定了用于制定本文件的程序及对其采取进一步的维护。特别需要注意的是,不同类型的ISO文件所需的批准准则是不同的。本文件按照ISO/IEC指令第2部分的编辑规则起草。(见www.iso.org/directives)。

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any patent rights identified during the development of the document will be in the Introduction and/or on the ISO list of patent declarations received (see www.iso.org/patents).

需要注意是,本文件中的一些要素可能涉及到专利权的内容。ISO不应负责识别任何及所有这些专利权问题。在本文件的制定过程中,任何已识别的专利细节将会列入引言和(或)ISO已接收专利声明清单中。(见www.iso.org/patents)。

Any trade name used in this document is information given for the convenience of users and does not constitute an endorsement.

本文件中所使用的任何商标名是为方便使用者而给予的信息,不构成背书。

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

与合格评定相关的ISO特定术语和表达的含义解释,以及在贸易技术壁垒(TBT)方面ISO遵从世界贸易组织(WTO)规则的信息,请见以下网址:www.iso.org/iso/foreword.html。

The committee responsible for this document is ISO/TC 46, Information and documentation, Subcommittee SC 10, Requirements for document storage and conditions for preservation.

技术委员会对 ISO/TC 46文件,信息和档案,委员会的附属委员会SC 10, 文件储存条件的要求负责

Introduction / 介绍

Archives, libraries and similar institutions store written and printed documents which they are obliged to retain on a permanent basis for cultural reasons and, in some cases, in order to meet legal requirements.

档案馆、图书馆和类似的机构在储藏手写或者打印文件的同时, 为了文化的传承他们有责任保持纸质文献的永久性。

Often, the condition of these documents is endangered for a number of reasons. One of these is related to the manufacturing process used for more modern types of paper.

引起纸质文献濒临灭绝的原因有很多,其中一个重要的原因就是当代纸张的造纸工艺导致。

In the industrial age, paper-making processes underwent significant changes. One of the processes affected was sizing, which, in industrial processes, was achieved by mixing additives into the fibre suspension before shaping the sheets. These additives included acidic substances like aluminium sulfate. The reaction of the sizing agent eventually leads to formation of free acids. The acids act as a catalyst for the hydrolysis of cellulose, making the material brittle. Climatic influences aggravate this process, air pollution and cellulose degradation processes are a further source of acid in paper.

在工业时代, 造纸过程中添加纤维悬浮液促进纸张的成型。这些添加剂包括酸性物质如硫酸铝。施胶剂的化学反应最终形成了自由酸。这些酸作为催化剂对纤维素进行水解,使材料脆化。与此同时,气候恶化加剧了这一反应, 空气污染和纤维素降解过程进加剧了纸张的酸化。

Another factor for paper stability is the raw material itself. For centuries, paper was made of textile fibres like linen, hemp or cotton rags which rather deliver stable, long-chain cellulose. The search for a more abundant raw material led to the invention to produce pulp out of wood by a grinding process. The resulting ground wood paper still contains most of the lignin and hemicelluloses, in addition to cellulose. The low pulp purity and the mechanical process causing a partial cutting of fibres lead to a much weaker paper. Compared to the older rag papers, ground wood paper is also less stable on the long run.

维持纸张稳定的另一个因素是原料本身。几个世纪以来,纸是采用纺织纤维如亚麻,大麻或棉抹布这些细胞稳定,纤维长的材料制造而成。为寻找更丰富的造纸材料出现了磨木浆,但里面含有大量木质素和半纤维素,纤维素。纸浆纯度低和机械过程导致的部分切割纤维脆弱。相比旧碎布纸、磨木浆纸更不稳定。

The problem of paper degradation due to acid has developed into a tremendous problem for archives and libraries. In addition to the processes for deacidifying single sheets, such processes having been used in conservation for a long time, the past few decades have seen new developments in technical processes which can be used on a large scale to retard the further decay of cultural assets as bound volumes and single sheets (“mass deacidification”).

对档案馆和图书馆来讲,纸张酸化导致的纸质退化已经对档案/文献/图书的储存带来也极大的问题。单品的脱酸工艺,已经使用了很长时间,为了解决酸化的严峻形势,随着技术的发展,批量脱酸技术应运而生(“大规模脱酸工艺”)。

The aim of deacidification is to appreciably improve the life expectancy of paper. This is achieved by adding an alkaline substance to neutralize existing acid and slow down future acidic degradation for at least some time (buffering, alkaline reserve). Deacidification cannot improve the actual physical properties of the paper, but in combination with proper storage, it can slow down further decay.

脱酸的目的是明显改善纸的寿命。这是通过添加碱性物质中和现有和未来会产生的酸性物质来减缓纸张的降解,延长纸张的寿命(缓冲,碱性储备)。脱酸不能改善纸的实际物理特性,但在适当的存储环境下,它可以延长纸张的寿命。

Without validated analytical methods, it is not possible to assess whether a paper has been deacidified, or to what degree deacidification has been successful. This Technical Specification compiles the suitable measurements.

没有实际的实验验证,不能评估/评定纸张是否已经成功脱酸,或在多大程度上脱酸,针对这些问题。本文件提供了评定脱酸的技术规范。

1 Scope / 范围

This Technical Specification defines test methods and minimum requirements for paper deacidification processes regarding their effectiveness and consistency.

本技术规范定义了关于纸张脱酸工艺有效性和一致的性测试方法和最低标准要求。

It is applicable for all large scale processes which offer deacidification of acid documents made of printed or hand-written paper.

本规范适用于所有大型的印刷或者手写的酸性文件的脱酸工艺

Possible negative side effects of deacidification processes on the treated objects are not the subject of this Technical Specification. However, some general recommendations for how to cope with these side effects are given in Annex A.

本技术规范不针对脱酸工艺潜在的副作用做论述,但是Annex A中有给出如何应对副作用的建议。

It is not specified either, which types of paper objects can be treated by large scale deacidification methods. Whatever currently available deacidification method is used, some objects might be excluded from treatment to avoid mechanical damage to paper and bindings or other unwanted side effects. The provider of the deacidification treatment should inform the customer about the limitations of the chosen method.

本规范没有限定哪种类型的纸张可以用大规模工艺进行脱酸。无论使用怎样的脱酸方法,都要做处理前的筛选,有潜在机械损伤纸,影响绑定效果或其他副作用不适合做脱酸。脱酸服务机构应告知客户如何筛选适合其脱酸工艺的材料。

2 Normative references / 引用标准

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

下列文件的全部或部分内容在本文件中进行了规范引用。凡是注明日期的引用文件,只有引用的版本适用于本标准;凡是不注日期的引用文件,其最新版本(包括任何修改)适用于本标准。

ISO 535, Paper and board — Determination of water absorptiveness — Cobb method

ISO 535,纸和纸板吸水性测定(可勃仪测定法)

ISO 536, Paper and board — Determination of grammage

ISO 536,纸和纸板克数的测定

ISO 776, Pulps — Determination of acid-insoluble ash

ISO 776, 纸浆 - 酸不溶灰分测定

ISO 5351:2010, Pulps — Determination of limiting viscosity number in cupri-ethylenediamine (CED) solution

ISO 5351:2010, 纸浆 - 本征粘度在铜乙二胺溶液中的测定

ISO 5626, Paper — Determination of folding endurance

ISO 5626, 纸张 - 耐折度测试

ISO 5630‑5:2008, Paper and board — Accelerated ageing — Part 5: Exposure to elevated temperature at 100 degrees C

ISO 5630‑5:2008,纸和纸板 - 加速老化 - 第五部分: 暴露在100C的高温环境下

ISO 6588‑1, Paper, board and pulps — Determination of pH of aqueous extracts — Part 1: Cold extraction

ISO 6588 - 1. 纸,纸板和纸浆 - 测定水提取物的pH值 - 第一部分: 冷提取

ISO 9184‑1, Paper, board and pulps — Fibre furnish analysis — Part 1: General method

ISO 9184‑1,纸,纸板和纸浆 - 纤维组成分析 - 第一部分:一般方法

ISO 9184‑4, Paper, board and pulps — Fibre furnish analysis — Part 4: Graff “C” staining test

ISO 9184-4, 纸,纸板和纸浆 - 纤维组成分析 - 第四部分:格拉夫/Graff“C”染色试验

ISO 10716, Paper and board — Determination of alkali reserve

ISO 10716,纸和纸板-碱性储备量的测定

3 Terms and definitions术语和定义

For the purpose of this document, the following terms and definitions apply.

ISO/TS 18344:2016适用于本标准的术语和定义

3.1 accelerated ageing 加速老化

artificially induced ageing under laboratory condition by increasing temperature and sometimes changing humidity or exposure to light in order to accelerate chemical reactions in paper like hydrolysis or oxidation to simulate processes usually occurring under natural condition but at a much slower speed

人工老化技术就是:在实验室把纸张通过增加温度,改变湿度或增加光照模拟在自然条件下老化很慢的过程,来加速纸张的水解和氧化。

3.2 alkaline reserve 碱性储备量

compound like calcium or magnesium carbonate neutralizing acids in paper

化合物如碳酸镁/钙中和纸中的酸

3.3 average degree of polymerisation 平均聚合度

average number of anhydroglucose units (monomers of cellulose) in the cellulose macromolecule

在纤维素大分子中脱水葡萄糖单位的平均数量 (单体的纤维素)

3.4 batch process 装订本(批量)脱酸工艺

deacidification process for a definite quantity of documents

有确定文件数量的批量脱酸

3.5 continuous process 散装脱酸工艺

deacidification process for an indefinite quantity of documents

非确定文件数量的批量脱酸

3.6 deacidification 脱酸

neutralization of the organic and inorganic acids in the paper and deposit of an alkaline reserve as buffer against any subsequent acidic activity on paper

中和纸中的有机和无机酸从而形成一定碱性物质来缓冲任何后续纸张中的酸性物质,防止纸张再度酸化

3.7 extract pH 提取pH值

value obtained in a water extract after the paper has been extracted under defined condition.

在特定的条件下液态提取纸张中的pH值

Note 1 to entry: Value measured with a glass electrode immersed in a definite quantity of water in which paper is dispersed in small pieces.

注:玻璃电极浸入定量且有小片的纸张分散的水中提取数值

3.8 folding endurance 耐折度

common logarithm of the number of double folds required to cause rupture in a strip of paper

以常用对数(对折)引起纸张破裂

3.9 mass deacidification 批量脱酸

process of paper deacidification on a large scale

有规模的纸张脱酸工艺

3.10 process validation 脱酸效果验证

securing an operation according to preset parameters determined at processed objects

根据预设参数指标,对比脱酸处理后的指标,从而来验证脱酸效果。

3.11 routine monitoring 常规监测

monitoring carried out at regular intervals during normal operations

在正常操作期间定期进行监测

3.12 side effects 副作用

any unintended consequence caused by the execution of a treatment process

脱酸后任何非预期的结果

3.13 test paper 测试纸

paper with characteristics defined in this Technical Specification, which is deacidified together with original documents and then analysed

本技术规范中定义的特性纸张,与脱酸对象一起进行脱酸处理然后进行分析。

3.14 uniformity of deacidification 脱酸的均匀性

homogeneous distribution of the alkaline reserve and pH across the entire sheet and within whole book blocks

在整张纸/整本书的pH碱性储备的分布情况和pH值

4 Principle 原则

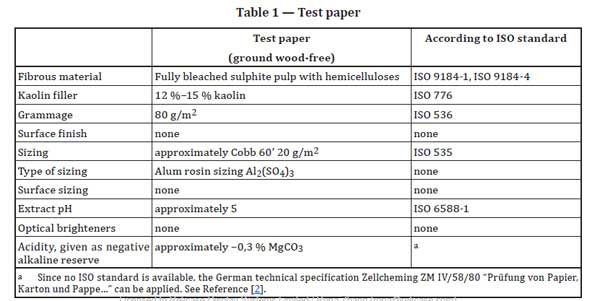

Specified uniform test papers are treated together with customer’s documents in a deacidification process. Afterwards, the test papers are examined using standardized test methods. The test papers are acidic and similar in their properties to common paper qualities produced in the period from around 1870 onwards. The usage of such papers ensures reliable results and allows comparing different batches, deacidification methods and treatment plants.

测试纸与客户的文件一起进行脱酸处理。然后,使用标准化的测试方法对测试纸进行检测。测试纸是酸性的,其属性类似1870年左右生产的普通纸品。使用测试纸是为了确保结果的可靠性,可用来比较不同批次,不同的脱酸方法和不同的处理设备/厂房。

NOTE It is to be emphasized that successful tests according to this Technical Specification cannot guarantee that all documents treated in the process are deacidified to the same degree as the test papers. The result of a deacidification treatment strongly depends on the properties of the treated object, such as porosity, thickness, sizing, coating and acidity of the paper, etc. Therefore, it is impossible to guarantee that certain pH levels and alkaline reserve amounts are achieved in each object by the deacidification treatment. A passing of the tests means, however, that there is a high percentage of successfully treated objects.

注意: 需要特别指出的是,根据本技术规范,不能保证全部被脱酸的材料会取得与测试纸同样的脱酸效果。脱酸处理的结果很大程度上取决于被脱酸的材料的属性,如孔隙度、厚度、大小、涂层和纸张的酸度等。因此,不可能保证批量脱酸后,每个单位上有同样的pH值和碱性储备数量。然而,通过脱酸处理后基本上都是可以达到脱酸指标。

5 Requirements 要求

5.1 General / 总则

This Technical Specification defines test methods for “process validation” (initial testing) and “routine monitoring”. Process validation is used to prove that a technique fulfils its defined purpose. Routine monitoring is used to check that the effectiveness determined by process validation is being achieved in the course of the actual work. Routine monitoring, therefore, is based on process validation.

本技术规范定义了工艺效果的验证方法(初始测试)和“常规监测”。工艺验证是用来证明该技术能满足其定义的内容。常规监测是用来检查在实际工作的过程中工艺的有效性是能够达到的。因此,常规监测建立在工艺验证(初始测试)的基础上的。

For “process validation”, extended test procedures should be carried out before and after accelerated ageing of the samples, including measurements of pH value, alkaline reserve, uniformity of deacidification and degree of polymerisation.

对于“工艺验证”,要对测试样品加速老化前后做进一步的测试,包括pH值,碱性储备,脱酸的均匀度和聚合度的对比测试。

For “routine monitoring”, alkaline reserve of the test papers is examined.

“常规监测”,测试纸要做碱性储备量的检测。

5.2 Sampling 样品

5.2.1 Material 材料 / 原料

Both process validation and routine monitoring are performed using samples of test paper, some of which are deliberately not subjected to the deacidification process serving as a reference.

工艺验证和常规监测使用的是测试纸样品,其中有些是故意不把脱酸效果做好作为比较素材。

5.2.2 Procedure 过程控制

All samples should be examined within four weeks after treatment has been completed (including post treatment measures).

脱酸处理后,四周之内对样品进行一次检测(包括处理后的测量)

Before the paper is examined, any loose residues occurring as a side effect of the deacidification process should be removed by brushing.

在纸张检测前,任何会影响检测的残留物质都应该用刷子清掉

5.3 Process validation 工艺验证

5.3.1 Frequency of sampling 采取样品的频率

A complete process validation is required every four years and, additionally, following

每隔四年要进行一次完整的工艺验证,当然有工艺变化的部分也要验证

— changes to the process technology, 工艺技术更新/改变的部分

— changes of chemical components or their supplier, 供应商或者化学配方的变化

— changes of the test paper for routine monitoring. 用于常规监测的测试纸的变化

The process validation is valid for all treatment devices of a production site that use the same process and technology.

工艺验证适用于所有使用相同的工艺和技术的脱酸设备

5.3.2 Sample quantities and preparation of samples 样品的数量和准备

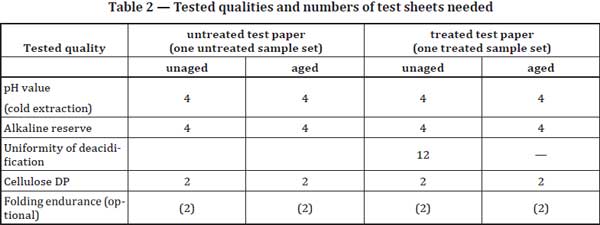

The process validation is performed using identical test papers (i.e. same production batch). A quantity of 32 (+4, if folding endurance is included) test sheets, size A5 or larger, is needed for the necessary testing (see Table 2) of one treated sample set. Four treated sample sets are necessary for the process validation. The untreated sample set included, the sum of test sheets for one complete process validation is therefore 148 (+20, if folding endurance is included).

工艺验证是通过使用相同测试纸进行(即同一生产批次的测试纸)。根据测试表,需要32张测试纸(+ 4,如果也进行耐折度测试),根据测试需求纸张A5大小或更大(见表2)集体进行处理。进行工艺验证必须要准备4套处理过的样品。包括未经处理的样本集,一组完整工艺验证的需要的测试纸张数量是148张(+ 20,如果也进行耐折度测试)。

For batch processes, the test papers should be placed into bound volumes which are thicker than 3 cm and feature a size of at least A5. For the first sample set, 32 (+4) test papers are placed evenly throughout the bound volume starting from page number 10.

The test papers should be centred vertically and placed as close to the spine as possible. The test papers should not extend outside the book block. The second sample set is prepared the same way, but placed in a different position in the treatment chamber. The third and fourth sample set should be treated on another day, and if applicable, in another treatment device. The positions of the samples in the chamber should be documented adequately.

装订本处理过程,测试纸应该放在装订本里,书本厚度至少3厘米厚且至少是A5纸张。第一组样本测试,32(+ 4)张测试纸均匀的放置在整个合订本里(从页码10开始)。测试纸应尽量置中垂直放置尽可能靠近书脊。测试纸不能扩展到书以外。第二组样本集合以同样的方式准备,但放置在不同的位置。第三和第四组样本改天处理,如果条件允许,请在另一个处理设备中进行。在整个操作中,样本位置应充分记录。

NOTE Service providers can supply a constructional drawing of the deacidification device with the report and mark the positions of the books containing the test papers.

注意:脱酸技术公司提供脱酸设备的施工图纸及报告和注明测试纸在书中的位置供参考。

For continuous processes, the test papers of one sample set should be treated alternating with sheets of original items. After further treatment of 100 sheets of original items, the second sample set should be treated to the same pattern as the first. The third and fourth sample sets should be treated according to the first two sample sets, but on a different day, and, if applicable, in another device.

在散装工艺验证时,测试纸应与处理材料交叉放置,当处理到差不多100张时,再以同样的方式处理第二套样品。第三和第四个样本集改天以同样的方式处理,如果条件允许,在另一个设备中进行。

5.3.3 Test methods and minimum requirements 测试方法和最低要求

5.3.3.1 Accelerated ageing 加速老化

Perform accelerated ageing of 10 (+2) test sheets of each of the four sample sets and 10 (+2) untreated test sheets as described in ISO 5630‑5:2008, Clause 4 to 9.2.

根据ISO 5630‑5:2008, Clause 4 to 9.2, 4组测试样品中10(+2)张测试纸进行加速老化,未处理的10(+2)张不进行老化处理

Test tubes selected for this study shall be perfectly gas-tight and large enough to accommodate paper strips pre-cut for further measurements. It is required to perform aging for all samples simultaneously, in the same laboratory oven, using one type of a glass tube for all samples.

选择的测试管必须结实,绝对密封并且空间足够大保证纸张未裁切前可以放入。所有的样品老化处理要同时进行,在同一个烘箱里,用同一种型号的玻璃试管。

NOTE To ensure perfect airtightness of testing tubes, the following steps could be taken:

— original tube caps supplied with glass tubes could be exchanged for caps made of material with higher resistance to mechanical and thermal stresses (e.g. polyphenylsiloxane);

注意: 为确保试管的绝对密封, 请按以下步骤操作:

--用更高级的试管冒代替原始的试管冒(如:聚苯基硅氧烷材质)

— sealing material – PTFE or silicone gaskets and o-rings should be avoided, fluoroelastomers are advisable (e.g. Viton);

-- 密封材料 - PTFE 或者silicone gaskets and o-rings这三种要杜绝使用,推荐使用氟橡胶 (如:Viton)

— tightening of the tube with the use of the dynamometric wrench equipped with a tube cap holder, to ensure good repeatability of obtained sealing.

--请用试管冒上配备的测力扳手来拧紧试管,确保完好密封

5.3.3.2 pH value pH值

The pH value has to be measured in an aqueous extract as described in ISO 6588-1.

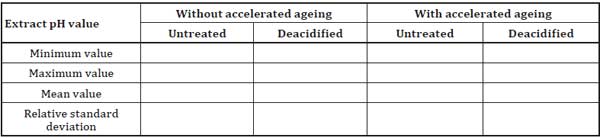

The average results and the average and the relative standard deviations should be given for treated paper with and without ageing, and the results should be expressed to two significant digits.

根据ISO 6588-1在液体中提取pH值

要测出加速老化和未加速老化的脱酸纸张的平均结果,平均值和相对标准偏差,结果必须是两组有效值

The measured pH of the paper following deacidification has to be higher than 6,5 (before accelerated ageing).

处理过的纸张pH值必须要高于6.5(在加速老化之前)

NOTE 1 The pH value of an aged sample will normally be lower compared to those of the non-aged sample. For a given paper, ageing after deacidification should only lead to a small reduction of its pH value. It is possible that the pH value measured after accelerated ageing will level out at around 6,5, even though an alkaline reserve is still present. This is particularly true of the pH value on the paper surface which is usually one unit lower than the pH value of the cold extract. Under these conditions, however, this kind of paper can still be described as being neutral.

通常加速老化之后的pH值会低于未加速老化的pH值。通常脱酸之后再加速老化pH只会受到很小的影响。尽管还有碱性储备量,加速老化后pH值仍会保持在6.5左右。通常对同一张纸而言,表面测出的pH值低于通过冷抽提取的pH值。但是,基于这些条件下,这些纸张仍被视为中性值。

The pH value discussed here applies solely to the described test papers. If original papers are examined as well, special agreements on an acceptable final pH value should be reached with the customer, as the achieved pH value depends very much on the original composition of the paper.

这里所讲的pH值只是适用于测试纸。但在检测原始纸张,要与客户先谈定一个可以接受的pH值,因为处理后的pH值很大程度取决于原始纸张自身的成分与状态。

NOTE 2 In addition to this measurement of aqueous extract pH value, measurements of surface pH value are sometimes performed. The surface pH measurement is a faster method compared to extraction pH measurement to judge the pH value of a paper. If applied correctly (see Reference [3]), surface pH measurements also allow onsite measurements of original books and documents in libraries and archives and can also be used to follow the stability of deacidification on a longer timescale. However, surface pH measurement has its limits. It works well for acidic to neutral papers and also gives reasonable data until about pH 9. Usually, surface pH measurement has been successfully used with immersion treatments. Surface pH measurement may fail to give reliable results when larger amounts of alkaline reserve deposits are present at the paper surface and the solubility limit is reached.

注:在液态提取pH值时,有时也会采取表面pH值测量的方式。因为相比冷提抽取pH值表面测量是一种更快的方法。如果正确应用(见参考文献[3]),可在图书馆档案馆里现在测量书籍文件的pH值和而且对长期跟踪脱酸的稳定性非常方便。然而,表面的pH值测量有其局限性,适合测量酸性和中性,及pH不超过9的数值。通常情况下,表面的pH值测量已成功用于浸泡式处理。当大量的碱性储备在纸表面时,溶解已经达到极限,表面的pH值测量方法提供的数值就不太可靠

5.3.3.3 Alkaline reserve 碱性储备量

Determine the quantity of alkaline reserve of each of the four sample sets as described in ISO 10716. For determination of the dry matter content, it is in deviation to ISO 10716 sufficient for the purpose of this Technical Specification to weigh about 1 g to the nearest 0,001 g.

根据ISO 10716,检测四套样本的碱性储备量。测量干物质含量,以千分之一的方法称重缩小误差

The results, the average and the relative standard deviation should be given for treated paper with and without ageing, and the results should be expressed to two significant digits.

加速老化和未加速老化的脱酸纸张要测出pH值,平均值和相对标准偏差,结果必须是两组有效值

The minimum alkaline reserve is 0,5 mass % expressed as MgCO3.

脱酸处理后最小的碱性储备量是0.5%

NOTE Part of the total amount of alkaline substance applied to the paper by deacidification treatment is chemically converted (“consumed”) by the neutralization reaction, and the remainder is the “alkaline reserve”. The alkaline reserve ensures that the paper is resistant to acids acting upon it due to environmental influences or degradation reactions occurring after the deacidification process.

注:脱酸时,在中和作用这一化学反应过程中会产生碱性储备量。脱酸处理后产生的碱性储备量足够抵抗由于环境影响或纸张降解退化导致的酸化。

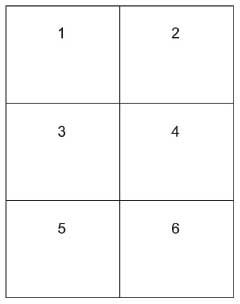

5.3.3.4 Uniformity of deacidification 脱酸的均匀性

The uniformity of deacidification is measured by quantitative determination of the alkaline reserve, expressed as mass % MgCO3, at six different segments of a treated sample. Figure 1 shows the cutting pattern for the segments.

在一个处理过的样本上选六个不同切片,通过碱性储备量的定量测定检测脱酸的均匀性,用% MgCO3表示。图1显示了切片的模式。

Figure 1 — Segments for the determination of alkaline reserve for uniformity test

表1 -- 用于碱性储备量均匀性测试的切片

As one A5 sheet of test paper is not sufficient for analysing uniformity due to the limited sample amount (for alkaline reserve 1 g of sample is required per data point), the measurement of the alkaline reserve of the six treated paper samples is carried out as described in ISO 10716, with the following amendments: Three A5 test paper sheets are cut into six rectangular, numbered segments of equal size according to the pattern shown in Figure 1. Then, the three pieces with same numbers are put together, divided into small pieces as described in ISO 10716, and the resulting pile is mixed well. About 1 g of pieces is weighed and treated as described in ISO 10716.

由于一张A5的测试纸的碱性储备量太少不够做均匀性的分析(碱性储备所需的量为:1 g /数据点),把3张A5测试纸张切成六个矩形, 根据ISO 10716所述对6个脱酸样本进行碱性储备量的测量,如图1所示把样品编号(1-6),标出每张纸上的碱性储备量。然后,如ISO 10716所述把三张具有相同的碱性储备量的纸张放在一起,分成小块,再混合起来。达到ISO 10716的标准。

Alkaline reserve measured for each section should be not less than 0,5 % by weight calculated as MgCO3 equivalent. In addition, the relative standard deviation of the six individual measured values is required to be less than 30 %. The lower the deviation calculated in this way, the better the uniformity of deacidification.

碱性储备每个切片应不小于0,5% (按重量等价计算氧化物)。此外,六个切片的相对标准偏差测量值必须小于30%。以这种方式计算的偏差越低,脱氧的均匀性越好。

NOTE 1 The results of these measurements describe the distribution of the added alkaline substance over the entire surface area of the sheet of paper, not its homogeneous distribution across its thickness/cross section. For the latter, no standardized routine methods are available.

注:这些测量的结果就是一张纸整个表面碱性物质的分布情况,而不是指均匀分布在其厚度/横截面(内里)。对于后者,目前没有标准化的常规检测方法。

NOTE 2 Some alternative methods exist which are able to address the uptake of deacidification reagent, in most cases, the concentration of cations is analysed. However, these methods do not suffice as a full displacement of alkaline reserve determination, as most of them are not fully comparable with the actual amount of alkaline reserve. However, to estimate whether mass deacidification was homogeneous they can serve as alternative.Potential methods are based on inductively coupled plasma optical spectrometry (ICP/OES) after the alkaline reserve was extracted by acid from the paper segments, X-ray-Fluorescence scanning or FTIR/NIR and other methods which reliably report the uptake of deacidification reagent.

注2:当下也有其他检测均匀性的方法,这些方法是通过是分析阳离子的浓度检测。然而,这些方法还是有缺陷的,因为大部分用这种方式测出的碱性值没有办法与实际量做比较。当然,这些可以也可以作为检测脱酸均匀性的方法。潜在的方法是基于电感耦合等离子体光学光谱(ICP / OES)碱性储备量,x射线荧光扫描或红外光谱/近红外光谱等方法,这些方法依赖于碱性残留量的报告。

5.3.3.5 Degree of polymerisation 聚合度

A pretreatment to remove the excess of alkaline reserve in the sample has to be performed as follows:

清除多余碱性残留量的步骤如下:

Disintegrate 1 g to 3 g of paper sample in a mixer for less than 30 s directly in 1,5 L, 0,1 M HCl at room temperature (for 3 g of paper sample with 2 % alkaline reserve this corresponds to >200 fold excess of acid when 1,5L are used). Rinse the sample thoroughly with water until washing water is neutral. Dry sample at room conditions according to ISO 5351:2010, Clause 8. The sample preparation should be adapted to the ingredients of the deacidification process.

在常温下,把混合纸样品分解到1 g至3 g放在1 5 L,0 1 M盐酸里浸泡30秒(3 g纸样品与2%碱性储备对应> 200倍过量的酸1时,使用5 L)。冲洗样品直到冲洗水变成中性的。根据ISO 5351:2010 条款8 在常温下干燥样品。根据脱酸程序准备合适的样品。

NOTE 1 ISO 5351:2010, Clause 8 requires 10 g of material, but 1 g is sufficient for the DP sample preparation in the present case. Determine the degree of polymerisation by measuring the viscosity average with CED as described in ISO 5351 before and after accelerated ageing. For determination of the dry matter content, it is in deviation to ISO 5351 sufficient for the purpose of this Technical Specification to weigh about 1 g to the nearest 0,001 g. The average results of the limiting viscosity number should be given for treated and untreated papers with and without ageing, and the results should be expressed in millilitres per gram.

根据ISO 5351:2010 条款8,要准备10g材料,现在的情况下,做DP(聚合反应)测试样品只需要准备1g就够了。根据ISO 5351要求对样品加速老化前后通过测量CED(内聚能密度)来检测聚合程度。对于干物质含量检测,根据ISO 5351 1‰ g偏差在本技术规范的允许范围之内。 处理/未处理和老化/未老化的样片都要给出特性粘度的平均值,结果应该用毫升每克表示。

After accelerated ageing, the limiting viscosity number of the treated paper has to be higher than that of the untreated paper.

老化过后处理过的样品其特性粘度值比没有经过处理过的样品要高。

NOTE 2 When looking at different deacidification treatments, the ratios of the limiting viscosity numbers of treated versus untreated papers after ageing can be compared if identical test papers are used.

注2: 对于不同的脱酸工艺,基于使用同样的测试纸,处理和未处理过的纸张加速老化后其特性粘度值可以进行对比。

For the calculation of DP, a [η]-DP relation for cellulose dissolved in CED is given in the formula below. The limiting viscosity number is converted to degree of polymerisation by DP = 0,9√(1,65 × [η]) (see Reference [5]).

关于DP(聚合度)的计算,特性粘度的数字转化为聚合度的DP = 0,9√(65×(η))(见参考文献[5])。(内聚能密度(Cohesive Energy Density))

注:溶解度参数是与分子间作用力有关的常数,定义内聚能密度(CED)的平方根为溶解度参数。

NOTE 3 The degree of polymerisation describes the average chain length of a polymer, in case of paper that of the mixture of cellulose and hemicelluloses. As the stability of paper is directly related to the chain lengths of (hemi) cellulose (longer polymer chains usually give stronger papers) this parameter can be considered as very important for the entire integrity of paper. In addition, it is a sensitive measure of cellulose degradation and hence very useful to address changes upon aging before and after deacidification. The sample amount required for analysis ranges between 75 mg and 750 mg for a triple determination depending on the sample DP (samples of lower DP require higher sample amounts). DP analysis using CED is limited to samples with little or no lignin content. Excess alkaline reserve is removed prior to DP analysis with an HCl treatment step. This HCl treatment only removes alkaline reserve which can in some cases interfere with DP measurement. The treatment does not degrade cellulose.[4]

注3:如果纸张成分是纤维素和半纤维素的混合物,聚合度描述了聚合物/混合物的平均链长。纸张的稳定性取决于聚合物长度,(半)纤维素(聚合物链长通常提供更强的纸张)对纸张的强度完整性/成型很重要。此外,它是一个非常重要的衡量纤维素的降解敏感参数,因此此参数用于对于比较脱酸处理前后的变化有重要意义。根据样本DP(如果样品的聚合度低,则需更多的样品量),根据样品DP的情况做一式三测的检测分析所要的样品量范围在75毫克和750毫克。使用CED小或者不含木质素的样品来做DP(聚合度)分析结果是有限的。在做DP分析前多余的碱性储备量用盐酸清理掉(HCl treatment)。盐酸只会清掉多余的碱性残留,不会降低纤维素。

NOTE 4 For the determination of DP, also other standards (Cadoxen, Cuoxam, see Reference [1]), and more sophisticated methods like size exclusion chromatography (SEC) coupled to light scattering do exist. They are either less frequently used/offered or in case of SEC more expensive. They also yield reliable cellulose DP data.

注4:关于聚合度的检测,其他标准(Cadoxen, Cuoxam,参考文件(1)),SEC也是较为成熟的方法。这些要么是不经常用,要么是费用太高。所以更倾向于纤维素聚合度参数检测。

5.3.3.6 Folding endurance (optional) 纸张耐折度的测量(非必选)

The machine direction folding endurance of the test papers shall be determined as described in ISO 5626 before and after accelerated ageing. The test instrument should be set with an appropriate tension to ensure that measurements give meaningful results.

NOTE For example, a typical setting for the MIT instrument would be to use a mass of 500 g for tension.

根据ISO 5626进行纸加速老化前后的机器定向折叠耐力测试。测试仪器应设置一个适当的张力,以确保测量是有意义的。注:比如,MIT仪器典型的设置应该是500克的张力。

Mean folding endurance and fold number are to be determined as defined by ISO 5626. After accelerated ageing, the fold number of the treated paper has to be higher than that of the untreated paper.

对折的方法与次数根据ISO 5626进行。加速老化后,处理过后的纸张折叠的次数高于未处理的纸张。

5.4 Routine monitoring 常规监测

5.4.1 Frequency of sampling and sample quantities 采样频率和样本数量

For routine monitoring, test papers from the same batch used in process validation should be used. For batch processes, a test set consists of four test sheets A5 or larger which are placed in bound original volumes thicker than 3 cm before deacidification as described in 5.3.2. For continuous processes, the test papers of one test set should be treated alternating with sheets of original items.

进行常规监测时,每批处理应该使用同一批次的测试纸。批处理脱酸过程时,如在5.3.2表述,测试集由四张A5测试纸或更大纸张组成,随机放在不低于3厘米的书本里。在散件的处理工序中,每一个测试集都应该与要处理的材料交叉放置处理。

The frequency of routine monitoring is one test set per production day and apparatus for batch processes and one test set per every five production days and apparatus for continuous processes.

常规监测的频率是钉装本每个工作日每个仪器检测一组,散件每5个工作日每个仪器做一组检测。

The sheets are distributed randomly, but their position should be documented adequately.

纸张是随机摆放的,但是要做追踪标记。

5.4.2 Test methods and minimum requirements 测试方法和最低要求

5.4.2.1 Alkaline reserve 碱性储备量

The quantity of alkaline reserve shall be determined as described in ISO 10716.

The minimum requirement for alkaline reserve is 0,5 mass % expressed as MgCO3. The greater of 0,5 mass % or 2/3 of the alkaline reserve obtained in process validation (5.3.3.4.) should be reached in routine monitoring.

ISO 10716定义了碱性储备的标准。碱性储备的最低要求是0.5%,在常规检测中脱酸工艺最后的碱性储备量不得低于0.5%或者2/3。

5.4.2.2 pH measurement (optional) pH值检测 (非必选)

The aqueous extract pH value has to be determined according to ISO 6588‑1.

The pH value of the paper after deacidification has to be higher than 6,5. Additionally, it has to be at least as high as the pH value measured during the process validation (5.3.3.2) minus 0,5 pH units.

液态提取pH值要参考ISO 6588 - 1。脱酸后纸张的pH值要高于6,5。此外,该值不得低于工艺验证过程中的pH(5.3.3.2)的 0、5 pH

NOTE In addition to this measurement of aqueous extract pH, measurements of surface pH are sometimes performed. The surface pH is a faster method compared to extraction pH to judge the pH status of a paper. If applied correctly (see Reference [3]), surface pH measurements also allow on-site measurements in libraries and archives and can also be used to follow the stability of deacidification on a longer timescale. However, surface pH measurement has its limits. It works well for acidic to neutral papers and also gives reasonable data until about pH 9. Usually, surface pH measurement has been successfully used with immersion treatments. Surface pH measurement may fail when larger amounts of alkaline reserve deposits are present at the paper surface and the solubility limit is reached.

注:在液态提取pH值时,有时也会采取表面pH值测量的方式。因为相比冷提抽取pH值表面测量是一种更快的方法。如果正确应用(见参考文献[3]),可在图书馆档案馆里现在测量书籍文件的pH值和而且对长期跟踪脱酸的稳定性非常方便。然而,表面的pH值测量有其局限性,适合测量酸性和中性,及pH不超过9的数值。通常情况下,表面的pH值测量已成功用于浸泡式处理。当大量的碱性储备在纸表面时,溶解已经达到极限,表面的pH值测量方法提供的数值就不太可靠

6 Report 报告

During both process validation and routine monitoring the data should be documented in a way which is understandable for the customer. The testing laboratory shall include the following in the written report:

为方便客户理解,在工艺验证和常规监测时两组数据应以同样的方式记录。测试实验室书面报告应当包括以下几点:

a) the number and extent of the batch and/or order; / 每批/每个订单的数量和进展程度

b) the dates of treatment and period and final date of reconditioning; / 处理的日期和周期,及最后整理的日期

c) the date and place of testing; 测试的日期与地点

d) any other observation made directly related to the deacidified material (e.g. same batch or last examination before treatment of this respective customer) that may be of importance regarding deacidification treatment; /任何其他与脱酸材料有关的调查(如同一批或每个客户脱酸处理前最后的检测)对脱酸处理都是很重要的;

e) any deviations from this Technical Specification and any circumstances that may have affected the results; 任何与该技术规范不同和任何会影响处理结果的因素

f) for process validation: test results obtained when testing as specified in 5.3.3.2, 5.3.3.3, 5.3.3.4, 5.3.3.5 and 5.3.3.6 (optional), both on untreated test papers as well as on treated test papers.

关于工艺验证:处理及未处理的纸张都根据5.3.3.2, 5.3.3.3, 5.3.3.4, 5.3.3.5 and 5.3.3.6 (optional)步骤进行的结果检测,

In addition: test results obtained when testing as specified in 5.3.3.2, 5.3.3.4, 5.3.3.5 and 5.3.3.6 (optional), both on untreated test papers as well as on treated test papers, all of which have been subjected to accelerated ageing (in accordance with 5.3.3.1). All data should be expressed as stated in this Technical Specification or in the relevant standard referred to.

另外:根据5.3.3.2,5.3.3.4,5.3.3.5和5.3.3.6(可选)的测试结果,对未经处理以及处理过的测试纸都加速老化处理(按照5.3.3.1)。所有数据应以本技术规格书或其他提过的相关标准表述。

For routine monitoring: Test results obtained when testing as specified in 5.4.2.1 and 5.4.2.2. (optional), both on untreated test papers and on treated test papers. The results obtained during process validation should be used as reference data. All data shall be expressed as stated in this Technical Specification or in the relevant standard referred to. If the results of the first determination fail the limits of the used standard, a second determination is needed and should be denoted.

常规监测: 对未经处理和处理过的测试纸 根据5.4.2.1 5.4.2.2(可选)做出监测结果。验证过程中获得的结果应作为参考数据。所有数据应以本技术规格书或其他提过的相关标准表述。如果第一次验证的结果没有达到使用标准,需要做第二次验证。

g) for process validation: A statement that the tested deacidification process meets or fails to meet the requirements of this Technical Specification. In the latter case, the specific reason shall be stated.

关于工艺验证:声明中有脱酸测试的结果符合或不符合本技术规范的要求的。不符合要求的要写明具体原因。

For routine monitoring: A statement that the tested routine job meets or fails the requirements of this Technical Specification. In the latter case, the specific reason should be stated.

常规监测:一份声明中有日常工作测试符合或不符合本技术规范的要求的。不符合要求的要写明具体原因。

NOTE A sample test record form is given in Annex B.Annex B中的样品测试记录

Annex A (informative / 信息)

Negative side effects and insufficient deacidification / 副作用和不充分的脱酸

Large scale deacidification processes may lead to negative side effects like bleeding of colours (of stamps, inks, etc.), white deposits of deacidification particles on the surface of papers and bindings or slight colour changes of treated papers. The occurrence of such negative side effects is strongly dependent on the type of process and the nature of the treated objects.

大批量的脱酸工艺会存在如晕色(章,墨水等)的副作用,在脱酸过的纸张上有白色碱性颗粒挡住字迹或者微微的改变一点颜色。这种副作用的产生很大程度上取决于是什么工艺和被脱酸文件的状态。

Although providers of large scale deacidification treatments try to reduce the negative side effects as much as possible, it is impossible to totally avoid them within a mass treatment of very different paper objects. The same holds true for the deacidification itself which may be insufficient in some cases.

虽然提供批量脱酸工艺的供应商已经尽最大努力去减少这种副作用的影响,但不可能100%的避免这中情况。同样的对脱酸工艺本身来讲,会有脱酸不充分的情况。(不充分要怎么发现与弥补?)

For this reason, providers of deacidification processes should indicate any process-specific side effects known to them and, before placing an order, the customer should examine these using suitable samples and weigh up risks and opportunities for each individual job, depending on the objectives of the measures. The customer then has to decide whether he considers the possible risks to be reasonable and acceptable, taking due consideration of the cultural and historical significance and/or where appropriate, the artistic value of the items.

出于这个原因,脱酸技术中心要明示客户该技术会带来的任何潜在的问题,客户根据实际要被脱酸的材料,在下单之前要先做样品脱酸测试权衡风险和机遇。然后根据文献的文化与历史意义或者其艺术价值,决定这个副作用是否合理和可以接受?

Whatever the case may be, in addition to the methods of testing, test papers and books described here, every customer is, of course, free to carry out his own tests on any paper of his choice, preferably on original items wherever this is possible.

无论采取怎样的脱酸工艺,在哪里进行脱酸,每个客户都可以在要进行脱酸处理的测试纸与书籍中选取样品进行免费脱酸试验。

It goes without saying that any process for deacidifying paper should ensure the unconditional preservation of the information contained on the paper.

理所当然的,任何脱酸工艺机构要无条件地保护被脱酸文献内容的保密性。

Annex B (informative / 信息)

Sample forms for documentation 文档的表格示例

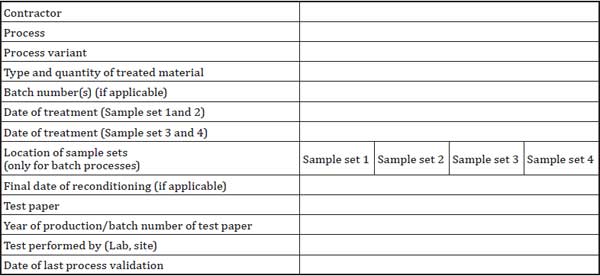

B.1 Sample forms for documentation — Process validation test record

工艺验证测试记录表格

Table B.1 — General data 通用数据

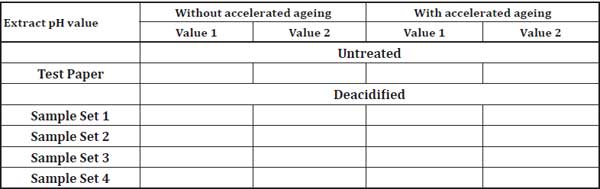

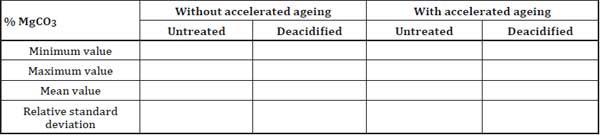

Table B.2 — pH value (cold extraction) (5.3.3.2)

冷抽提取pH值

Table B.3 — pH measurement:pH值测量

Mean value and relative standard deviation from four valid sample sets / 从四组有效样品中提取平均值及相对标准差

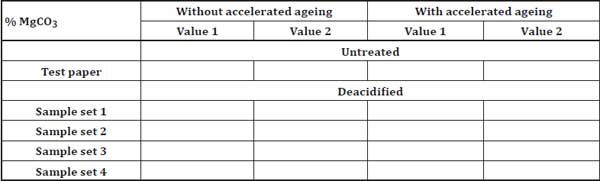

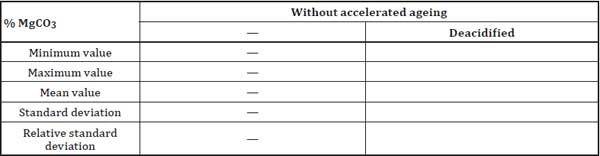

Table B.4 — Alkaline reserve (5.3.3.3) / 碱性储备量

Table B.5 — Alkaline reserve measurement: 碱性储备量测量

Mean value and relative standard deviation from four valid sample sets

从四组有效样品中提取平均值及相对标准差

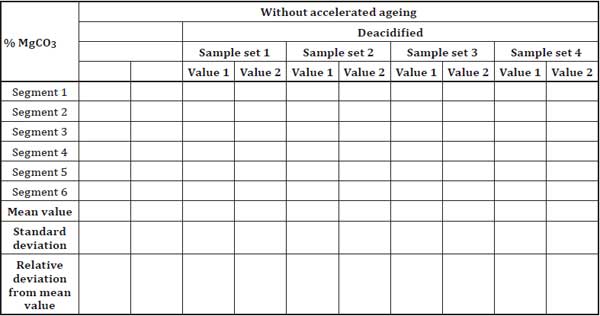

Table B.6 — Uniformity of deacidification (5.3.3.4)

脱酸的均匀性

Table B.7 — Uniformity measurement:脱酸均匀性测量

Mean value, standard deviation and relative standard deviation from four valid sample sets

从四组有效样品中提取平均值,标准差及相对标准差

...点击查阅完整